Description

Product Description

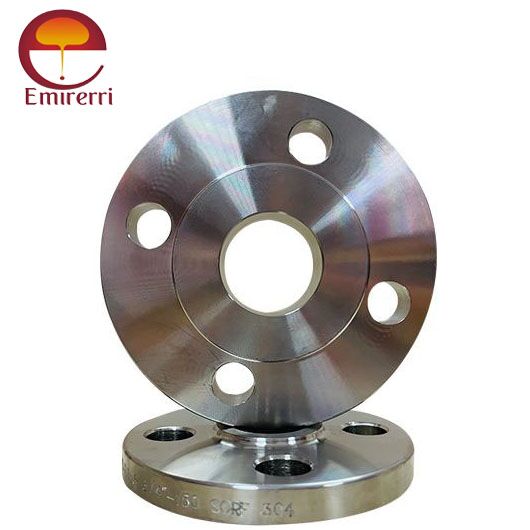

DIN Lap Joint Flange conforms to the standards set by the Deutsches Institut für Normung (DIN), which is the German Institute for Standardization. Here’s a detailed product description:

- Design: Similar to ANSI lap joint flanges, DIN lap joint flanges consist of two main components: a flat, circular disc (the “stub end”) and a ring or hub (the “lap joint”). The stub end is welded to the pipe or fitting, while the lap joint rotates freely around it, allowing for easy alignment during assembly.

- Materials: DIN lap joint flanges are available in various materials to suit different applications and operating conditions. Common materials include carbon steel, stainless steel, alloy steel, and other specialized alloys, depending on the requirements of the application.

- Sizes: These flanges are manufactured in a range of sizes to accommodate different pipe diameters and pressure ratings. DIN lap joint flanges are available in nominal sizes ranging from DN10 to DN2000 or larger, with pressure ratings ranging from PN6 to PN100 or higher.

- Facings: The flange face can be flat face (FF), raised face (RF), or ring type joint (RTJ), depending on the application requirements and sealing preferences.

- Standards: DIN lap joint flanges conform to the dimensional standards set forth by DIN, ensuring compatibility and interchangeability with other DIN-compliant components.

- Applications: Lap joint flanges are commonly used in piping systems where frequent dismantling and reassembly are required, such as in systems handling corrosive or abrasive fluids, or in applications with thermal expansion considerations.

- Assembly: During assembly, the lap joint flange is placed over the stub end, and the joint is sealed using a gasket. Bolts are then inserted through the holes in the lap joint and tightened, pressing the flange faces together and compressing the gasket to create a tight seal.

- Versatility: DIN lap joint flanges offer versatility in piping design and installation, allowing for easy alignment adjustments and disassembly without disturbing the entire piping system.

In summary, DIN lap joint flanges are a reliable and versatile solution for joining piping systems in various industrial applications, conforming to rigorous German standards for quality and performance.

Reviews

There are no reviews yet.