Description

Product Description

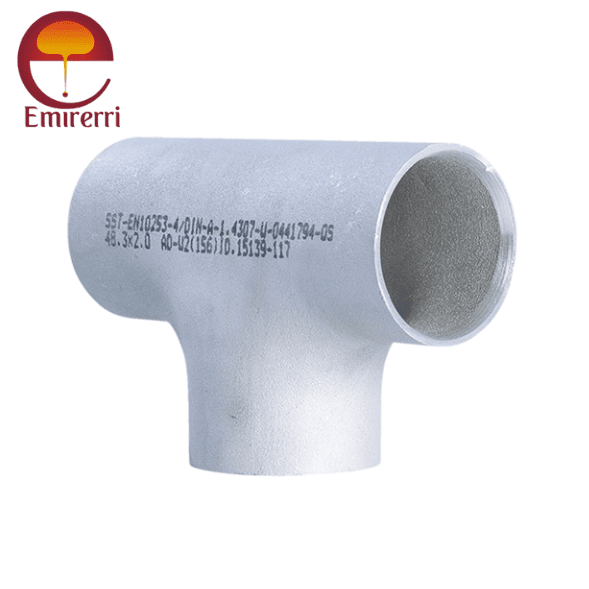

EN10253-1 is a European standard that specifies the technical delivery requirements for seamless and welded butt-welding fittings made of carbon steel and alloy steel. A tee conforming to EN10253-1 would adhere to these specifications, ensuring compatibility and quality in joining piping systems. Here’s a product description for an EN10253-1 tee:

- Material: EN10253-1 tees are typically constructed from carbon steel or alloy steel, chosen based on factors such as operating conditions, corrosion resistance, and mechanical properties. These materials undergo thorough testing and quality control to meet the specified chemical composition and mechanical properties.

- Design: The tee fitting follows a T-shaped configuration, featuring one inlet and two outlets, allowing for branching off in different directions. The design ensures smooth flow transition and minimal pressure drop within the piping system. EN10253-1 tees are available in seamless and welded construction, depending on the application requirements.

- Dimensions: EN10253-1 tees are available in a wide range of sizes and dimensions, conforming to European standards. These dimensions are specified to match the corresponding pipe sizes and schedules, ensuring proper fit and alignment in the piping system. The standard provides detailed specifications for dimensions such as outside diameter, wall thickness, and center-to-end dimensions.

- Butt Welding Ends: The ends of the tee are prepared for butt welding, following the requirements specified in EN10253-1. This involves the beveling and preparation of the pipe ends to ensure proper alignment and welding integrity. Butt welding provides a strong, leak-tight joint suitable for high-pressure and high-temperature applications.

- Standards Compliance: EN10253-1 tees comply with the standards set forth by the European Committee for Standardization (CEN), ensuring quality, performance, and safety in various industrial applications. Compliance with EN10253-1 standards ensures that the tees meet rigorous manufacturing and quality control requirements.

- Applications: EN10253-1 tees find applications across various industries, including oil and gas, petrochemical, chemical processing, power generation, and others. They are used for branching, diverting flow, and connecting different sections of piping systems, providing reliability and durability in critical applications.

In summary, EN10253-1 tees are essential components in piping systems, offering compatibility, durability, and integrity in joining pipelines through butt welding. Their adherence to European standards ensures they meet stringent quality and performance requirements for various industrial applications.

Reviews

There are no reviews yet.