Description

Product Description

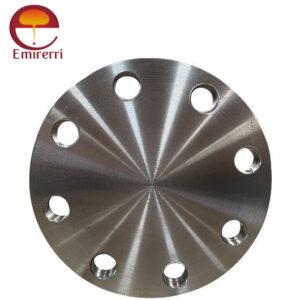

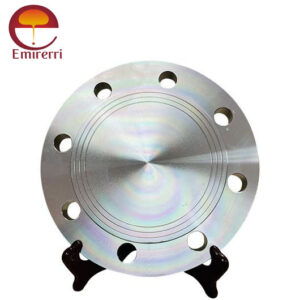

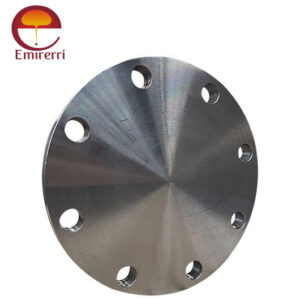

ASME B16.47 Series A blind flange is critical component in piping systems, designed to seal off or block the end of a pipe, valve, fitting, or equipment nozzle. These flanges are manufactured in accordance with the American Society of Mechanical Engineers (ASME) B16.47 Series A standards, which outline specific dimensions, tolerances, materials, and testing requirements.

The product description typically includes:

- Material: Blind flanges can be made from various materials such as carbon steel, stainless steel, alloy steel, or other materials suitable for the intended application. The material selection depends on factors such as pressure, temperature, corrosion resistance, and compatibility with the fluid being transported.

- Size: ASME B16.47 Series A blind flanges are available in a range of sizes, typically specified in nominal pipe sizes (NPS) or nominal pipe diameters (NPD). Common sizes range from 1/2 inch to 60 inches or larger, depending on the requirements of the piping system.

- Pressure Class: Blind flanges are rated according to their pressure class, which indicates the maximum pressure they can withstand at a given temperature. ASME B16.47 Series A blind flanges are available in various pressure classes, such as Class 150, Class 300, Class 600, Class 900, Class 1500, and Class 2500.

- Design Standards: ASME B16.47 Series A blind flanges conform to specific design standards established by ASME, ensuring consistency and compatibility with other ASME-compliant components in the piping system.

- Dimensions and Tolerances: The product description includes detailed dimensions and tolerances for the blind flange, including outer diameter, bolt hole diameter, bolt circle diameter, thickness, and other critical dimensions. These dimensions are crucial for ensuring proper fit and alignment within the piping system.

- Surface Finish: Blind flanges may have a specific surface finish requirement to ensure proper sealing and corrosion resistance. Common surface finishes include raised face (RF), flat face (FF), and ring type joint (RTJ), each suitable for different sealing methods and applications.

- Testing and Certification: Blind flanges are often subjected to various tests to verify their performance and quality, including hydrostatic testing, dimensional inspection, and material certification. The product description may include information on testing procedures and certifications to ensure compliance with industry standards and regulations.

Overall, ASME B16.47 Series A blind flanges play a crucial role in piping systems by providing a reliable and leak-proof closure for pipes, valves, and equipment, while ensuring safety, integrity, and performance in various industrial applications.

Reviews

There are no reviews yet.