Description

Product Description

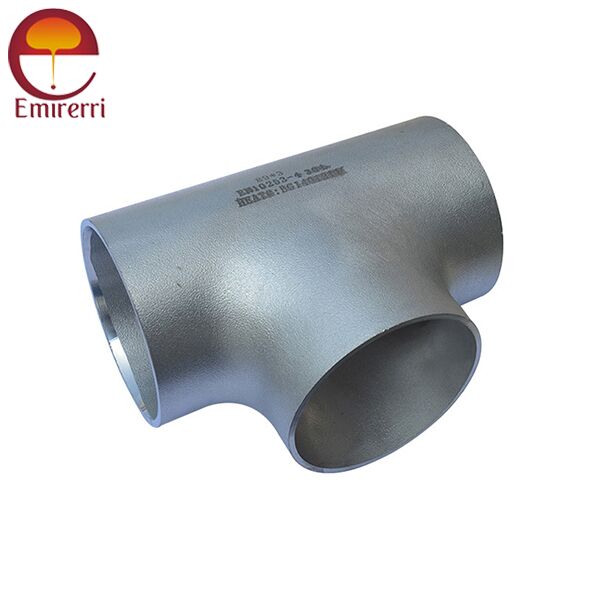

GOST 17376 Tee is a critical component designed for use in piping systems across various industries. It facilitates branching and distribution of fluid flow, ensuring efficient conveyance and optimal system performance.

Material: Fabricated from high-quality materials such as carbon steel, stainless steel, alloy steel, and other materials suitable for diverse operating conditions and applications.

Design: The butt weld tee conforms meticulously to the dimensions and specifications outlined in GOST 17376, ensuring seamless compatibility and interchangeability with other GOST 17376 fittings and pipes. Its design incorporates smooth transitions to minimize pressure drop and flow resistance, enhancing system efficiency.

Manufacturing Standards: Manufactured in strict compliance with GOST 17376 standards, our butt weld tees undergo comprehensive quality control measures to uphold the highest standards of performance and reliability.

Sizes: Available in a broad range of sizes, from small diameters to larger dimensions, catering to various pipe diameters and wall thicknesses for versatile application in piping system design and installation.

Applications: Suitable for a wide array of applications across industries including:

- Oil and gas transmission pipelines

- Chemical processing plants

- Petrochemical refineries

- Power generation facilities

- Water treatment plants

- Pharmaceutical industries

- Food processing plants

- HVAC systems

- And more

Features:

- Exceptional corrosion resistance for prolonged service life

- High mechanical strength and durability to withstand demanding operating conditions

- Precision manufacturing for seamless fit and alignment, ensuring leak-free performance

- Smooth transitions for efficient flow distribution and reduced flow turbulence

- Easy installation and maintenance, contributing to cost-effectiveness and operational efficiency

- Wide temperature and pressure range capability, ensuring adaptability to diverse operating environments

Certifications: Our GOST 17376 butt weld tees are accompanied by pertinent material certifications and can undergo additional third-party inspection and certification upon request, ensuring compliance with industry standards and regulations.

Customization: Tailored customization options are available to accommodate specific project requirements, encompassing special materials, coatings, dimensions, and configurations.

Quality Assurance: Each butt weld tee undergoes stringent quality inspections throughout the manufacturing process to ensure impeccable dimensional accuracy, material integrity, and reliable performance.

Packaging: Carefully packaged to prevent damage during transit and storage, ensuring the tees arrive at the customer’s location in pristine condition.

Reviews

There are no reviews yet.