Welcome to Emirerri Steel Manufacturer Pvt Ltd

- About us

- Products

Pipe Fittings

- Hot-Rolled Steel Coils

- Cold-Rolled Steel Coils

- Galvanized Steel Coils

- Stainless Steel Coils

- Standard

- Blogs

- Quality

- Contact

- Download

The JIS B2220 10K flange is a high-performance flange designed according to the Japanese Industrial Standards (JIS) with a pressure rating of 10K. This type of flange is widely used in piping systems across industries due to its reliability and adaptability.

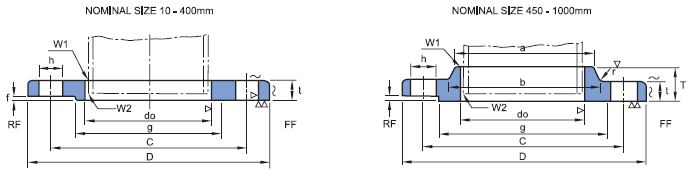

Nominal Dia. of Flange | Outside Dia. of Flange D | Sectional Dimensions of flange | Nominal Bolt Size | Welding | ||||||||||||

| Dia. of Bolt Circle C | Dia. Of raised Face g | Inside Dia. Of Flange do | Outside Dia. Of Applicable pipe | t | T | Dia. of Hub | Radius r | Raised Face f | Hole Dia. H | Number of Bolt Holes | ||||||

| a | b | W1 | W2 | |||||||||||||

| 10 | 90 | 65 | 46 | 17.8 | 17.3 | 12 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 2.5 |

| 15 | 95 | 70 | 51 | 22.2 | 21.7 | 12 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 3 |

| 20 | 100 | 75 | 56 | 27.7 | 27.2 | 14 | – | – | – | – | 1 | 15 | 4 | M12 | 5 | 3 |

| 25 | 125 | 90 | 67 | 34.5 | 34 | 14 | – | – | – | – | 1 | 19 | 4 | M16 | 5 | 3 |

| 32 | 135 | 100 | 76 | 43.2 | 42.7 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 40 | 140 | 105 | 81 | 49.1 | 48.6 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 50 | 155 | 120 | 96 | 61.1 | 60.5 | 16 | – | – | – | – | 2 | 19 | 4 | M16 | 6 | 3 |

| 65 | 175 | 140 | 116 | 77.1 | 76.3 | 18 | – | – | – | – | 2 | 19 | 4 | M16 | 6.5 | 4 |

| 80 | 185 | 150 | 126 | 90 | 89.1 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 6.5 | 4 |

| -90 | 195 | 160 | 136 | 102.6 | 101.6 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 6.5 | 4 |

| 100 | 210 | 175 | 151 | 115.4 | 114.3 | 18 | – | – | – | – | 2 | 19 | 8 | M16 | 7 | 4 |

| 125 | 250 | 210 | 182 | 141.2 | 139.8 | 20 | – | – | – | – | 2 | 23 | 8 | M20 | 7.5 | 4 |

| 150 | 280 | 240 | 212 | 166.6 | 165.2 | 22 | – | – | – | – | 2 | 23 | 8 | M20 | 8 | 5 |

| -175 | 305 | 265 | 237 | 192.1 | 190.7 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 5 |

| 200 | 330 | 290 | 262 | 218 | 216.3 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| -255 | 350 | 310 | 282 | 243.7 | 241.8 | 22 | – | – | – | – | 2 | 23 | 12 | M20 | 9 | 6 |

| 250 | 400 | 355 | 324 | 269.5 | 267.4 | 24 | 36 | 288 | 292 | 6 | 2 | 25 | 12 | M22 | 10 | 6 |

| 300 | 445 | 400 | 368 | 321 | 318.5 | 24 | 38 | 340 | 346 | 6 | 3 | 25 | 16 | M22 | 10 | 6 |

| 350 | 490 | 445 | 413 | 358.1 | 355.6 | 26 | 42 | 380 | 386 | 6 | 3 | 25 | 16 | M22 | 12 | 7 |

| 400 | 560 | 510 | 475 | 409 | 406.4 | 28 | 44 | 436 | 442 | 6 | 3 | 27 | 16 | M24 | 12 | 7 |

| 450 | 620 | 565 | 530 | 460 | 457.2 | 30 | 48 | 496 | 502 | 6 | 3 | 27 | 20 | M24 | 14 | 8 |

| 500 | 675 | 620 | 585 | 511 | 508 | 30 | 48 | 548 | 554 | 6 | 3 | 27 | 20 | M24 | 14 | 8 |

| 550 | 745 | 680 | 640 | 562 | 558.8 | 32 | 52 | 604 | 610 | 6 | 3 | 33 | 20 | M30 | 15 | 9 |

| 600 | 795 | 730 | 690 | 613 | 609.6 | 32 | 52 | 656 | 662 | 6 | 3 | 33 | 24 | M30 | 16 | 10 |

| 650 | 845 | 780 | 740 | 664 | 660.4 | 34 | 56 | 706 | 712 | 6 | 3 | 33 | 24 | M30 | 16 | 10 |

| 700 | 905 | 840 | 800 | 715 | 711.2 | 34 | 58 | 762 | 770 | 6 | 3 | 33 | 24 | M30 | 17 | 10 |

| 750 | 970 | 900 | 855 | 766 | 762 | 36 | 62 | 816 | 824 | 6 | 3 | 33 | 24 | M30 | 18 | 11 |

| 800 | 1020 | 950 | 905 | 817 | 812.8 | 36 | 64 | 868 | 876 | 6 | 3 | 33 | 28 | M30 | 19 | 12 |

| -850 | 1070 | 1000 | 955 | 868 | 863.6 | 36 | 66 | 920 | 928 | 6 | 3 | 33 | 28 | M30 | 19 | 12 |

| 900 | 1120 | 1050 | 1005 | 919 | 914.4 | 38 | 70 | 971 | 979 | 6 | 3 | 33 | 28 | M30 | 22 | 14 |

| 1000 | 1235 | 1160 | 1110 | 1021 | 1016 | 40 | 74 | 1073 | 1081 | 6 | 3 | 39 | 28 | M36 | 22 | 14 |

| *(1100) | 1345 | 1270 | 1220 | 1123 | 1117.6 | 42 | – | – | – | – | 3 | 39 | 28 | M36 | ||

| *1200 | 1465 | 1380 | 1325 | 1225 | 1219.2 | 44 | – | – | – | – | 3 | 39 | 32 | M36 | ||

| *1350 | 1630 | 1540 | 1480 | – | 1371.6 | 48 | – | – | – | – | 3 | 45 | 36 | M42 | ||

| *1500 | 1795 | 1700 | 1635 | – | 1524 | 50 | – | – | – | – | 3 | 45 | 40 | M42 | ||

2025 © All rights reserved by Emirerri Steel Manufacturer Pvt Ltd