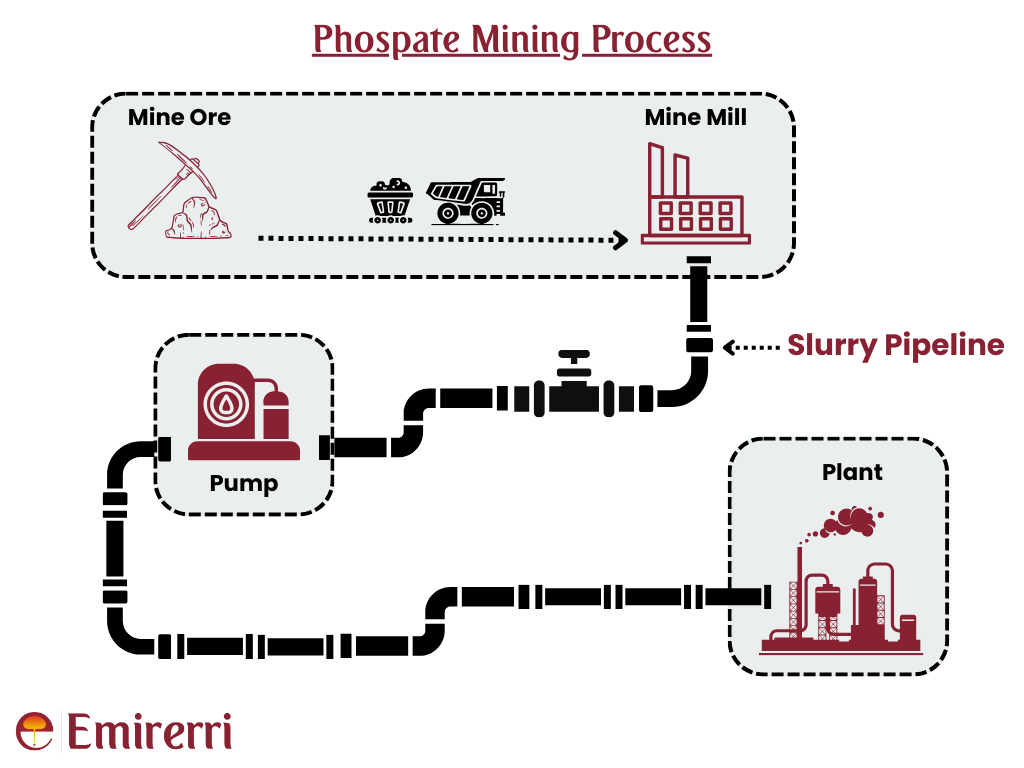

In the mining sector, the efficient transport of materials is crucial for operational success. One of the most effective solutions for moving mined materials is the slurry pipeline. Slurry pipelines have revolutionized how mining companies handle bulk materials, offering efficiency, safety, and cost-effectiveness. This blog explores the importance of slurry pipelines, their applications, and their role in the phosphate mining industry.

A slurry pipeline is a system designed to transport a mixture of solid particles and liquids over long distances. These pipelines are engineered to carry abrasive, dense slurries, which consist of solids suspended in a liquid medium, usually water. The pipeline ensures a continuous, reliable, and controlled flow, reducing the need for trucks or conveyor belts in mining operations.

A typical slurry pipeline system is composed of:

The adoption of slurry pipeline transportation in mining offers numerous benefits:

Cost-Effective: Reduces reliance on road transport, lowering fuel and labor costs.

Environmentally Friendly: Minimizes dust emissions and road congestion.

Reliable and Continuous: Enables uninterrupted transport of materials over long distances.

Safety: Reduces risks associated with truck transport in harsh mining environments.

Phosphate mining relies heavily on slurry pipelines due to the unique nature of phosphate rock processing. In phosphate mines, the raw material is crushed and mixed with water to form a slurry, which is then transported to processing plants. This method is particularly efficient for:

Choosing the right slurry pipeline material is critical to ensure longevity and reduce maintenance costs. Important factors include:

Slurry pipelines are indispensable in modern mining operations, particularly in the phosphate mining industry. By integrating slurry transportation piping systems and selecting the appropriate slurry pipeline material, mining companies can achieve efficient, safe, and sustainable transport of mineral slurries.

Whether for short-haul or long-distance slurry pipeline transportation, adopting the right slurry piping systems ensures optimized operations, reduced costs, and enhanced environmental performance.

2025 © All rights reserved by Emirerri Steel Manufacturer Pvt Ltd